Editor’s note: While process improvement initiates the change, automation paves the way for staying ahead of the curve. What was once considered a “nice to have” is now essential for competition. I strongly advise reading our comprehensive business process automation eBook, which will guide you through the next crucial steps once you successfully implement business process improvement.

Business processes include all the ways you get work done. Processes involve certain steps, best practices, and operating procedures that govern the completion of mission-critical tasks.

According to management theories like lean production and Six Sigma, the key to competitiveness is to continuously improve business processes for greater efficiency and effectiveness (crucially, this requires the reduction of variation in those processes).

What is Business Process Improvement?

Business process improvement (BPI) is the practice of making those positive changes, continually streamlining operations based on stakeholders’ input—both internal (managers, employees) and external (customers, industry partners, experts).

Most BPI takes one of two forms: It either removes flaws in your existing processes or introduces innovation, creating a better way to do what needs doing—a faster way to get the pickles on the burger, literally or metaphorically.

Importantly, BPI is not a one-time event but an ongoing refinement process. As businesses evolve, external factors change, and new technologies emerge, there is a constant need to adapt and optimize operations.

This adaptive mindset ensures that organizations remain competitive, agile, and responsive to the ever-evolving market demands and customer expectations.

Successful BPI initiatives can lead to numerous benefits, including increased productivity, reduced costs, enhanced customer satisfaction, faster time-to-market for products and services, and improved employee morale and engagement.

Additionally, BPI can help businesses stay compliant with industry regulations and standards, fostering a culture of continuous improvement that drives long-term success.

Business process change examples cover a wide range of operational improvements, such as:

- Speeding up cycle time

- Improving product quality

- Reducing costs

- Boosting employee engagement

- Creating better customer experiences

When we discuss BPI in such general terms, though, it can be tough to envision how the concept applies to your real-world operation. Here are a few business process improvement examples that illustrate specific possibilities—and hopefully get you excited about making some improvements of your own.

7 Real-Life Examples of Business Process Improvement

Refer these business process improvement case studies when a colleague asks, “What is an example of process improvement?” Then, keep reading to learn how BPI contributes to the cornerstone of digital transformation: intelligent automation.

1. Preventing Shipping Errors

The Company: A mid-sized wholesaler

The Scenario: This supplier provides components for manufacturers, delivering pallet loads directly to plants. In this instance, the delivery driver pulls up to the address on file only to discover it’s not a manufacturing facility; it’s clearly a residence.

The client runs a small business, and the credit card’s billing address belongs to the owner’s home, while the shipping address is for the manufacturing facility. Delivery staff has mixed up the client’s billing and shipping addresses, leading to a costly process defect.

The Business Process Improvement: Update operating procedure to require delivery staff to double-check shipping addresses against billing addresses. Create training materials (videos, online courses, written documents) and require all delivery drivers to complete the training. Verify that all relevant staff have viewed the materials.

Bonus Tip: Use a Learning Management System (LMS) to disseminate training materials, track employee education, and issue internal certifications for new or adjusted business processes.

2. Reducing Waste With Bulk Purchasing

The Company: A regional pharmacy chain

The Scenario: This pharmacy mixes topical medications on-site, blending various medicines into a base ointment. A pharmacist notices that they buy this ointment in one-ounce jars, and she uses 50 jars every day.

She further notes that their supplier offers a 50-ounce jar of ointment with a much lower per-ounce price point; the company could save money by switching their buying process.

The Business Process Improvement: Document the preference for bulk ointment purchases in official operating procedures. Train purchasing staff to default to the 50-ounce jar. Again, use a learning management system to deliver training materials and verify that staff has completed the training.

3. Planning For Process Failures

The Company: A large content marketing firm

The Scenario: Content writers conduct interviews with subject matter experts (SMEs) to get the material they need for innovative blogs and web pages. The writers follow an existing process map to go from blog idea to published post, which lists each step from creating the initial interview requests email to draft publication.

When everything goes according to plan, the process works perfectly. We call this the happy path. But in the real world, complications arise.

In this example, the SME may not show up for the interview. The internet connection could fail halfway through. Or the client could reject the draft entirely. These situations open the door for errors and threaten to derail publication schedules.

The Business Process Improvement: The company must start by documenting instances that veer off the happy path; writers themselves—the frontline staff in charge of the process—are the best source for noting these issues as they occur.

With writers documenting potential disruptions, the team can make a plan to handle each one to minimize publication delays. Then, as always, teams must document those improvements in the company’s operating procedures, with management first developing training materials on the new procedures and verifying the writers have completed the training.

4. Enhancing Safety Protocols

The Company: A major airline

The Scenario: The most crucial processes to optimize are those involving safety—and, as this example shows, that includes processes that veer off the happy path.

In this example, an experienced pilot is flying between US cities for aircraft repairs. The plane’s landing gear are stuck in the down position. While this doesn’t prevent flight, the pilot discovers that it does create excess drag.

Commercial airlines have rigid safety procedures before any flight can depart, including a pre-flight checklist. This aircraft completes the preflight checklist to permit takeoff, but the checklist doesn’t consider the additional drag that the stuck landing gear creates, leading to a fuel shortage before the plane reaches its destination.

Thanks to the disciplined process built over years of experience, the pilot checks fuel capacity by hand halfway through every flight. He discovers that he won’t have enough fuel to reach his destination and lands early for refueling.

The Business Process Improvement: This is an example of an internal innovation that the airline can scale across the entire fleet. Add mid-flight fuel checks to pilot operating procedures. Provide training and certification to ensure ongoing compliance.

5. Streamlining Confusing Workflows

The Company: A medical facility

The Scenario: Workers’ compensation appointments are time-consuming for the entire staff, requiring multiple employees to complete certain steps. The patient may see any number of physicians in any number of specialties along the way, and their paperwork gets passed to numerous departments, including intake, scheduling, and billing, among others.

To make matters more complicated, the employees filling those roles are not consistent from one shift to the next.

The facility estimates each patient journey to encompass nearly 100 steps, and most of these steps vary every time. Some patients require blood work,;some need imaging scans; and others need emergency care for broken bones or other injuries.

It can be confusing and time-consuming for employees to know which step needs to be completed next and by whom, especially when the facility has several patients at once.

The Business Process Improvement: Automating the workers’ compensation process from start to finish would make it easier for employees to know which step to complete next and automate some of the more menial tasks.

Some paperwork is standardized, for example, and can be completed using robotic process automation (RPA) and artificial intelligence (AI). Automating the creation of new patient files based on intake paperwork would improve the process dramatically.

Bots could confirm patient sign-ins and form completion, automatically sort documents into relevant folders, and print documents and literature for the patient to review and sign.

The facility could also use RPA and AI to notify new patients automatically, by email, that they have outstanding paperwork. Upon completion of these papers, the system would move the patient forward to the next step in the journey and notify the relevant employees.

Providing a way for participants to log in to a dashboard and clearly see their tasks reduces confusion and mistakes, allows for greater efficiency, and creates a chain of accountability within the system.

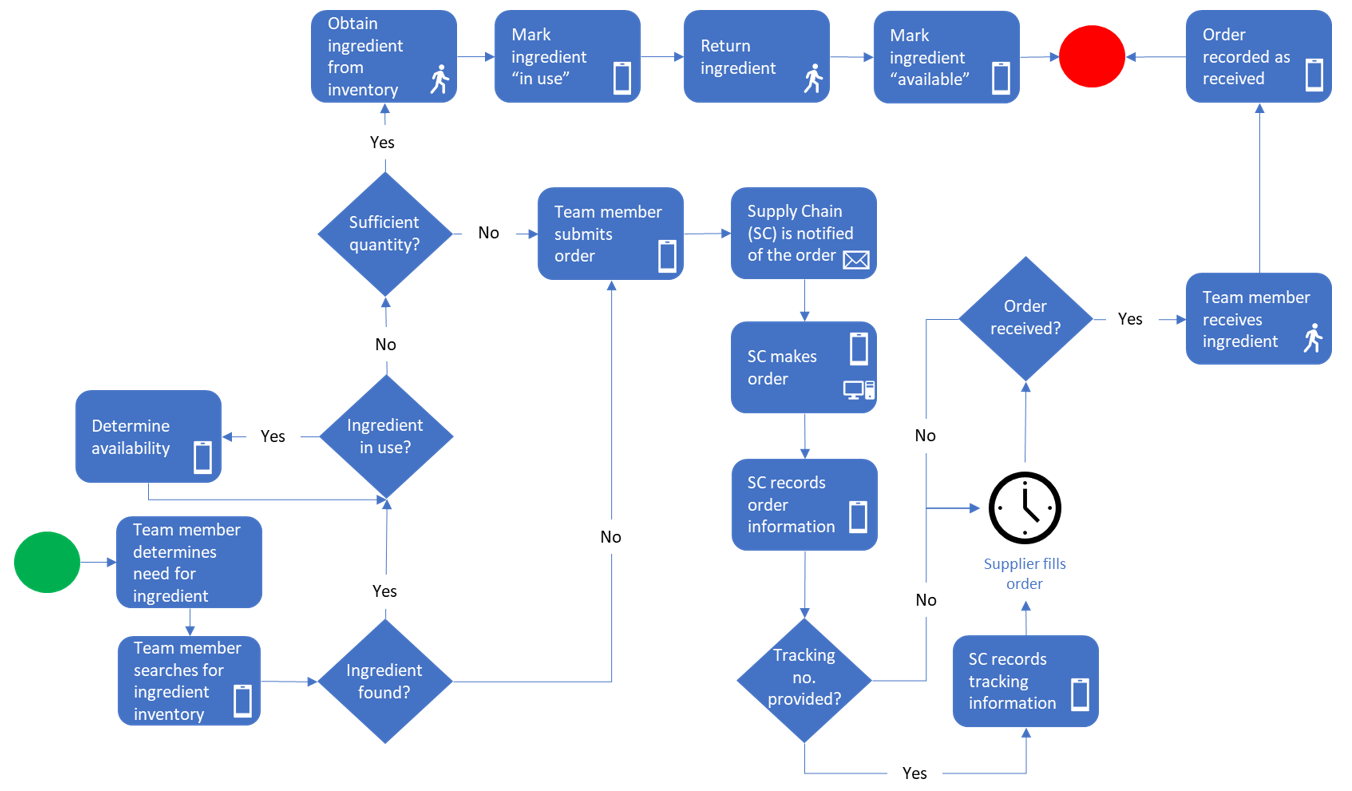

6. Improving Inventory Management

The Company: A food and beverage company that specializes in research and development

The Scenario: This company’s tracking and ordering of necessary supplies could be described as chaotic at best. Chefs operate on different teams, working on different projects, but they all use ingredients from a common supply storage. If one team member needs a particular ingredient, he must check the inventory in storage to see if he can find it.

If he can’t, it doesn’t necessarily mean the company doesn’t have the ingredient; perhaps it is simply in use by another team at the moment. Often, this scenario leads to unnecessary supply ordering, sometimes accompanied by costly rush delivery fees.

To make matters worse, each supplier has different order records and protocols. For example, some provide samples while others do not. Some also provide documents outlining their available ingredients and ordering policies.

But due to a lack of organization and tracking, employees often can’t find these documents and end up requesting them from suppliers multiple times or placing orders incorrectly.

The process is confusing and rife with inefficiencies, leading to duplicate orders, frustrated suppliers, and high project costs.

The Business Process Improvement: Establishing a central management system for inventory management, order tracking, and document organization is paramount.

Instead of manually checking storage for an ingredient, employees could use a mobile application to “check out” ingredients from an automatically tracked inventory, eliminating confusion around availability.

Order submissions for ingredients should also take place within the central application, so each team member can see if an order is already pending. Additionally, each supplier’s protocols and relevant documents should be centralized and easily accessible during the ordering process.

7. Improving the SLA

The Company: An Insurance Firm

The Scenario: The insurance company’s claims adjudication process, which involves resolving insurance claims, used to take the team 59 days to complete. Interestingly, the contractual Service Level Agreement (SLA) for this process was set at 60 days. Therefore, the team’s goal was to finish the process just one day ahead of the SLA schedule.

The Business Process Improvement: By applying lean and continuous improvement principles, the Prime Vector team (a business process improvement solution provider) transformed the process, reducing it to just 59 minutes while maintaining efficiency. This illustrates the significant impact of these methods on streamlining operations.

Also Read: Business Process Optimization: A Simple Framework For Every Industry

Common Business Process Improvement Techniques:

1. Lean Six Sigma

It is a data-driven methodology to reduce defects, minimize waste, and improve efficiency. It combines Lean principles (focus on waste reduction) and Six Sigma (focus on process variation reduction). Using statistical analysis, Lean Six Sigma identifies problem areas, implements changes, and monitors results for continuous improvement.

2. Kaizen

Kaizen, originating from Japan, means “continuous improvement.” It involves making small incremental changes regularly to enhance processes, eliminate inefficiencies, and optimize workflow. Kaizen fosters a culture of continuous improvement by involving all employees and encouraging their active participation in suggesting improvements.

3. Agile

Originally developed for software development, Agile has gained popularity across various industries. It emphasizes iterative and incremental progress, frequent customer feedback, and collaboration among cross-functional teams. Agile enables businesses to adapt quickly to changing requirements, deliver value early, and stay customer-focused.

These techniques aim to enhance efficiency, reduce waste, and increase customer satisfaction. You must tailor these methods to suit the specific needs of your business for more streamlined and effective operations.

Steps to Implement Business Process Improvement

Effective Business Process Improvement is an iterative process that requires dedication, collaboration, and a commitment to excellence from all involved parties. Let’s take a look at the primary steps you can take to improve your business processes.

- Define Clear Goals and Metrics: Establish clear and measurable objectives for your process improvement initiative, such as cost reduction, efficiency gains, or customer satisfaction improvement. Set specific Key Performance Indicators (KPIs) to track progress and success.

- Involve Stakeholders and Foster Collaboration: Engage key stakeholders from different departments and levels of the organization. Encourage open communication and collaboration to gather valuable insights and ideas for optimizing processes.

- Embrace Continuous Improvement: Approach process improvement as an ongoing and iterative journey. Continuously analyze data, gather feedback, and refine processes to sustain long-term efficiency gains and ensure a culture of continuous improvement within the organization.

Business Process Improvement And Digital Automation

Most digital automation projects start with some form of BPI. That’s because automation is most effective for standardized processes. A process with a high degree of variation is extremely hard to automate; essentially, you’re dealing not with a single process but with many processes that lead to the same conclusion.

Even with an intelligent automation platform that uses Artificial Intelligence (AI) and machine learning, that variation may reduce effectiveness.

By implementing BPI, decision-makers can identify ideal operating procedures prior to automation—and there are compelling reasons to pursue digital automation. Intelligent automation leads to extraordinary advantages, from freeing human staff for more profitable work to improving data accuracy across systems.

The Nividous intelligent automation platform automates optimized business processes by combining three advanced technologies into a single comprehensive system:

- Robotic Process Automation (RPA). Nividous RPA bots work through existing digital infrastructure to complete rule-based tasks 24/7. Unattended bots operate in the background, handling back-end data processes, while attended bots streamline customer-facing work through participation with human staff.

-

Artificial Intelligence. Nividous Smart Bots enhance automation with AI technologies like Intelligent Document Processing (IDP), Optical Character Recognition (OCR), machine vision, machine learning, Natural Language Processing (NLP), and predictive analytics.

Together, this AI allows Smart Bots to work with data similar to a human worker, including higher cognitive tasks like data recognition, classification, and validation.

- Business Process Management (BPM). The Nividous platform’s Control Center is a BPM solution that strings together discrete tasks into end-to-end hyperautomation. It orchestrates human workers and RPA bots to manage entire process maps from start to finish—including step-by-step reporting and live-process visibility.

This process map shows a high-level view of the revised inventory management and ordering process.

Also Read: Business Process Vs. Workflow: What’s The Difference?

3 Business Process Improvement Case Studies: Combination of BPI and Intelligent Automation

- One leading logistics provider automated review and verification of shipping documentation, reducing TurnAround Time (TAT) by 60% and saving nearly 900 work hours per month.

- An insurance firm implemented the Nividous platform to automate customer case classification and payment reconciliation, reducing manual work by 90% and boosting overall productivity by 80%.

- A top manufacturing company automated invoice processing from end to end with Nividous RPA Smart Bots incorporating machine learning, computer vision, and OCR. That automation eliminated data entry errors, reduced TAT by 90%, and saved more than 1,000 staff hours per month.

Read more examples of intelligent automation through the Nividous platform.

Ready to try business process automation for yourself?

The Nividous Quick Start Program guarantees production of a trained RPA bot in less than a month, from identifying eligible processes to roll-out.

It’s the perfect way to start the journey to hyperautomation, turning your own business process improvement example into a business case for broader digital transformation.

See how business process automation can transform your business.

Sign up for a personalized, guided demo of the Nividous platform today.

Click any term below to learn more.

Intelligent Automation

The seamless integration of RPA, AI, and workflow automation tools to automate complex, end-to-end business processes for higher efficiency and agility.

RPA (Robotic Process Automation)

Software bots that replicate human actions to perform rule-based, repetitive tasks with speed and accuracy.

Agentic AI

An advanced form of AI that autonomously makes decisions and takes actions to achieve defined goals without human intervention.

Generative AI

AI models, such as ChatGPT and Gemini, that can create original content—text, images, or code—based on natural language prompts.

Low-Code Platform

A visual development environment that enables users to build applications quickly using drag-and-drop components and minimal coding.

Hyperautomation

A strategic approach that leverages multiple technologies—including RPA, AI, and low-code platforms—to automate business processes end-to-end across the enterprise.

![Business Process Automation: Your Complete Guide [2023]](https://nividous.com/wp-content/uploads/2023/09/Business-Process-Automation-Your-Complete-Guide-2023-Blog-Feature.webp)