For decades, the manufacturing industry has used physical robots to assemble, test, and package products. These robots help in streamlining the assembly line but the industry still struggles to keep back-office processes fast and simple—primarily due to unskilled labor, time-intensive processes, obsolete supply chain management systems and frequently changing regulatory requirements.

In order to overcome these pain points, manufacturing companies are turning to process automation tools such as Robotic Process Automation (RPA), artificial intelligence (AI), Business Process Automation (BPA), and Intelligent Document Processing (IDP).

These technologies can be combined and used as key enablers for end-to-end process automation. Many companies are using this strategy to streamline complex back-office operations such as vendor communication, payment processing, report generation, and more.

In this article, we’ll discuss the role these technologies play in manufacturing process automation and some success stories.

Surveys show that 43% of manufacturers already use robotic process automation, while a further 43% plan to deploy RPA initiatives.

Although all types of automation are helpful tools in the manufacturing process, one type of automation stands a head above: RPA. Robotic Process Automation is uniquely suited to aid in manufacturing speed and efficiency—we’ll explain its features, as well as the features of other types of automation, below.

What is RPA?

Robotic Process Automation (RPA) is a technology that uses software robots to automate and streamline repetitive and rule-based tasks in various business processes. Organizations across industries already use RPA tools to optimize operations by offloading mundane and time-consuming tasks from employees and enhancing efficiency and productivity.

At its core, RPA involves creating a set of instructions that guide the software robots to perform specific tasks. These robots can navigate through various applications, systems, and data sources like a human would, but with the advantage of speed and accuracy. Keep reading as we dive deeper into the type of tasks/ functions for which you can use RPA.

Find Out: Everything that you need to know about RPA.

What are the benefits of RPA in Manufacturing?

The manufacturing industry has seen industrial automation empowered by physical robots. But there is a need for disruptive technology such as Robotic Process Automation in manufacturing that can help businesses to focus more on product innovation and core strengths instead of day-to-day repetitive tasks that are critical but mundane in nature.

Robotic Process Automation enables the automation of rule-based operations to enhance process execution speed and accuracy. Further, RPA solutions are easy to implement and do not require coding skills. RPA also seamlessly integrates with existing legacy systems without costly and time-consuming software development.

Companies can get started with a pilot project by choosing a specific set of operations and observe tangible and measurable results within weeks of implementation.

Benefits of Robotic Process Automation in the manufacturing industry include:

- Up to 40% reduction in operational cost

- Increased control over processes

- Optimized employee performance

- Significantly lower downtime and increased quality

Also Read: Top 11 Benefits Of RPA (With Real Examples)

What type of tasks can be automated by RPA in the manufacturing industry?

RPA bots can automate a range of operations, and if combined with a set of advanced intelligent automation technologies, the scope of automation gets even more comprehensive.

Tasks related to inventory management and order processing, supply chain management, quality control, production monitoring, compliance and reporting, and invoice processing are most suitable for RPA-enabled automation. HR, finance, and customer support departments also benefit from deploying RPA to automate manual processes.

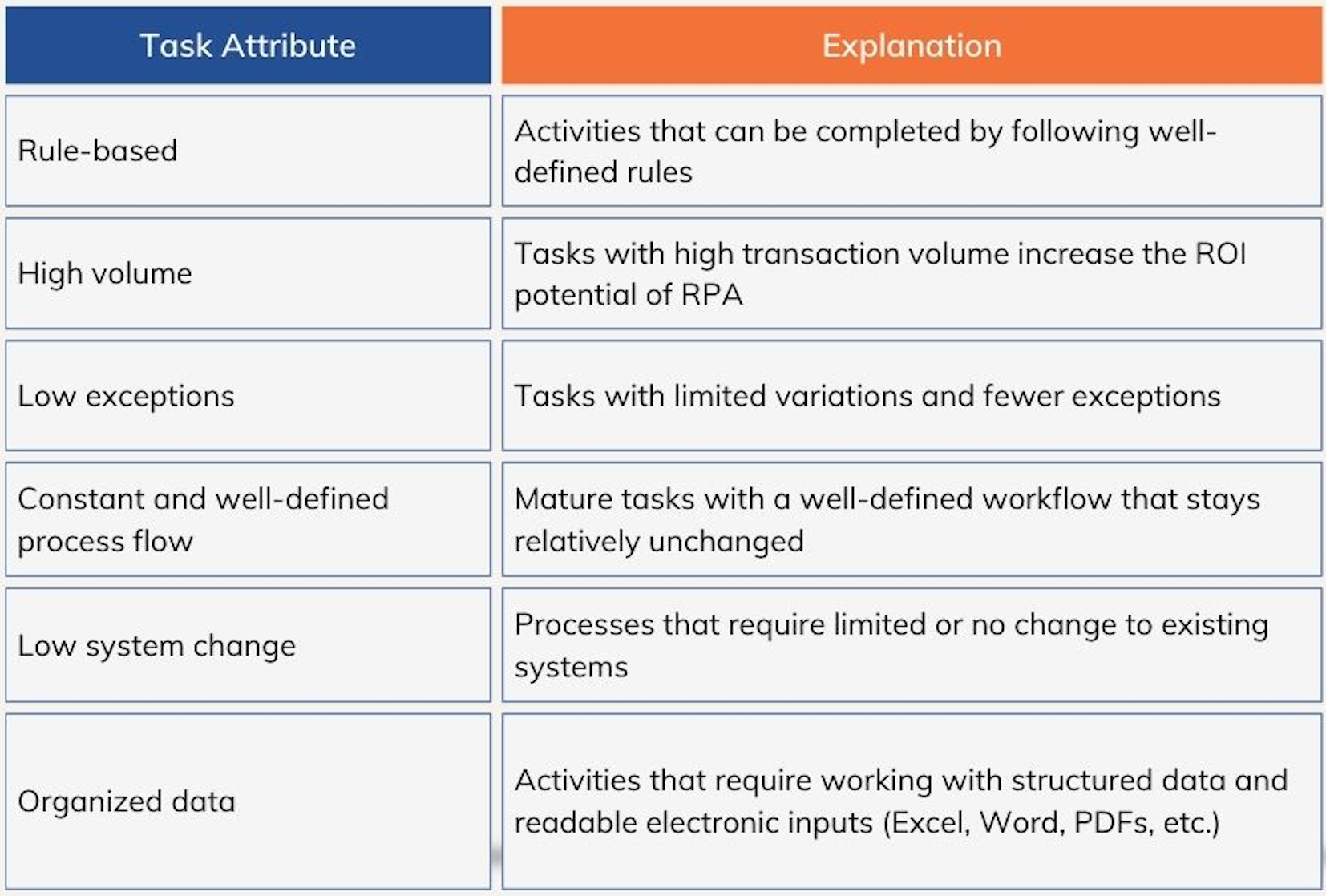

Below is the list of attributes that make a task or activity likely to benefit from RPA:

For example, extracting and updating data from multiple enterprise-grade applications (like ERPs, CRMs, or, third-party regulatory portals) are highly time-consuming tasks that are prone to errors.

It can take weeks—and significant manual labor—to complete these tasks, since all these systems are often not well integrated. RPA bots can fill the integration gap by automating such operations within the existing systems.

Ready to unlock the potential of Intelligent Automation in manufacturing?

Watch our expert-led on-demand webinar and discover how AI, ML, low-code automation, and RPA are reshaping manufacturing operations and driving unprecedented efficiency.

Let’s take a closer look at some of the areas within manufacturing that can benefit from RPA:

RPA Use Cases & Examples in Manufacturing Industry

1. Purchase Order Creation

The manual process for purchase order creation can be daunting for organizations dealing with multiple product categories. With the help of RPA, the entire PO creation process can be automated, enabling 100% accurate and speedy results.

Bots are capable of extracting data from independent systems, seeking email approval from concerned departmental heads, and processing the request of PO generation.

2. Inventory Management

Real-time monitoring of inventory levels is required to ensure that demand can be met. It’s possible to automate inventory monitoring, stock-level notifications, and product reordering when the levels go below a set threshold. All this can be done with minimal human intervention.

As an added bonus, implementing RPA automatically results in the creation of a detailed audit trail. Live dashboards and reports also provide information about business patterns and internal workings that can reveal potential bottlenecks. These insights can be used to remove the disruptions within the supply chain for process optimization and improvement.

3. Vendor Communication

Day-to-day communication between vendors, customers, and the internal workforce requires a large amount of manual effort. For instance, to answer a question about the status of goods shipped, a customer service rep may need to find the email communication, track the shipment status in the ERP system, send an update to the customer, and close the case.

RPA can take over the entire process by opening the email, reading the text, downloading attachments, logging into the ERP portal, determining the status of the shipment, replying to the customer, and moving on to the next customer email.

The entire process requires no human intervention with the exception of unexpected events. Such automation can eliminate up to 65% of the manual effort, enabling employees to resolve more customer queries in less time.

Beyond RPA: Artificial Intelligence (AI), Intelligent Document Processing (IDP), & Business Process Automation (BPA) In Manufacturing

Advantages Of AI In Manufacturing

Artificial intelligence, or AI, is a technology that can employ machine learning for complex tasks. When combined with RPA, it can enable automation of tasks that are much more complicated than what is possible with RPA alone. It’s a valuable type of tech that can be especially useful in some of the following manufacturing use cases:

1. Predictive Maintenance

Manufacturing companies use physical robots and high-quality industrial machines to check off complex tasks and build complicated products. In this type of industry, machine downtime is dangerous and costly. AI can predict machine downtime and maintenance needs to keep all physical processes running smoothly.

2. Price Forecasting

AI can be employed for budgetary calculations and price forecasting for raw materials. AI-assisted automation can perform calculations based on historic prices of materials, predicting future prices and adding this information to corporation budgets.

This type of work transcends rule-based behaviors and helps make sense of what RPA bots are doing. It brings an extra level of intelligence to whatever process it automates, meaning that more complex pricing is possible with AI assistance.

3. Computer Vision-based Quality Control

In manufacturing, computer-based intelligence can be used to measure the quality of outgoing products. AI automation can even flag lower-quality products for human inspection.

4. Shipping Automation

AI-driven technology can make shipping processes faster and smoother by recognizing data, sorting packages, and making complex shipping calculations in an instant.

Advantages Of IDP In Manufacturing

IDP uses AI technologies to extract structured data from unstructured documents. IDP can also be used to classify the documents before data extraction to increase the quality of the extracted data. This data can then be used for dashboards, reporting, or in other downstream processes as needed.

Interested in harnessing IDP for your corporation?

Learn more about IDP with our free webinar covering basics, benefits, and global data!

In the manufacturing field, IDP can be especially useful for invoice processing. In manufacturing, there are many types of invoices, products, and departments; invoices also arrive through different channels and in different formats.

IDP has the power to transfer that information to a database, purchase order, or other semifinal destination so that humans can interact with the prepared invoice data.

Advantages Of Business Process Automation In Manufacturing

BPA, also called Business Process Management (BPM), is an automation strategy that encompasses various management techniques and technologies. These can include big-picture organizational plans, employee-specific plans of action, and software plugins that enhance your existing technology.

In manufacturing automation, BPA can assist with connecting the dots between RPA, AI, and IDP. This addition allows you to completely automate end-to-end processes that include human performed tasks in addition to the steps automated by the other technologies we have discussed.

Tasks that require human performance will be automatically assigned to a user, role, or queue, and the system will track their performance of this task, creating process related tracking data that can be used to diagnose bottlenecks and other problems with the process.

This data can also be combined with data tracking the automated tasks and business side data to give great high-level insight into the real performance of your business processes.

The bottom line is this: The ultimate goal for automation in manufacturing is not to automate a single task, but an entire process—and that requires multiple technologies, not just RPA.

3 Success Stories of RPA in Manufacturing

All the specific technologies mentioned above are native to the Nividous platform. They are already integrated within a single platform that allows for repeatable solutions to be implemented quickly and easily.

All components are built within a single development environment, which further speeds the time to production. Best of all, everything is built and maintained by Nivdous. There is no need for any additional licensing or multiple confusing vendor relationships.

| Our goal is to employ unique combinations of automation technology to achieve the most efficient, end-to-end system for each client. |

Though manufacturing clients have unique processes and concerns, the solution to most challenges is the same as for any other industry: You need comprehensive, intelligent automation that uses a combination of RPA, AI, IDP, BPA, and other technologies.

Here’s how other manufacturing companies have used Nividous to successfully automate their processes:

1. A high-tech manufacturer uses Nividous RPA to automate back-office operations.

Problem: High skilled employees spent a considerable amount of time performing manual processes across multiple systems. Job requisitions, purchase orders, contract compliance, invoice reconciliations, and customer requests were incredibly time-consuming and created a negative impact on the success of a product launch.

Solution: The Nividous team automated more than 20 business processes using Nividous RPA to streamline back-office operations related to administrative, human resources, accounts, and purchase departments. The customer was able to achieve a 60% improvement in overall process complementing time and reduce operational costs by 40%.

Read the complete success story of RPA in manufacturing back-office operations.

2. A leading telecom company automates procure to pay using Nividous RPA.

Problem: The end-to-end process of setting up a field network involved various manual operations related to purchase management, timely status updates to vendors, invoice processing, etc. The key challenge was to complete the whole process with speed and security, where the data was collected and updated from independent systems.

Solution: Nividous first standardized the end-to-end process within the core ERP system and then enabled process automation to RPA eligible operations. This helped in eliminating third-party access to their legacy systems making it secure and error-free. Nividous Bots performed outlook, excel, and web automation to reduce the average process handling time by 50%.

Read the complete success story of RPA in the P2P process.

3. A leading manufacturing company automates its end-to-end invoice processing.

Problem: The company receives hundreds of invoices from multiple vendors. The manual process of transcribing data from different types of invoices into SAP required employees to spend a significant amount of time and effort.

The manual operations were highly time-consuming and delayed the processing considerably. The complete process was further delayed due to several approvals from different departments.

Solution: Nividous Bots having natively embedded machine learning, computer vision, and OCR capabilities were deployed to read details from several unstructured data sets and feed them into SAP with very high accuracy.

Moreover, the Bots present the extracted data with a confidence score (customizable) using an intuitive interface allowing the user to locate, review and annotate corrections with ease.

Read the complete success story of invoice processing using RPA.

Streamline Your Manufacturing Process Automation with Nividous

The success stories mentioned above provide a solid foundation to understand why leading manufacturing companies rely on the Nividous intelligent automation platform for their automation needs. From automating repetitive tasks and reducing human errors and processing times with Native RPA capabilities to leveraging AI capabilities for predictive maintenance, quality control, and demand forecasting, the platform takes care of everything. In addition, the native BPM component ensures end-to-end process orchestration and optimization. This comprehensive platform empowers manufacturers to enhance productivity, reduce operational costs, ensure consistent product quality, and respond swiftly to market changes.

Ready to Get Started with Manufacturing Automation?

Schedule a free demo to see how Nividous can help you cater to your unique business needs in today’s fast-paced environment.

FAQs About Automated Manufacturing

What does automation mean in manufacturing?

The Nividous platform enables the combined use of multiple technologies to facilitate faster work and better time management. These benefits can be obtained company-wide, in multiple departments, freeing up dozens (if not hundreds) of employees to focus on more complex tasks where human intelligence is most necessary.

How is automation used in manufacturing?

The applications of automation in manufacturing are virtually endless. Different automation technologies can be employed for tasks like:

- Predictive maintenance

- Price forecasting

- Workflow predictions

- Quality control

- Database management

- Shipping management

- Invoice processing

- Document data extraction

- Purchase order creation

- Inventory

- Vendor management

Each manufacturing company is unique, but Nividous has found that many operational and back-office manufacturing processes can be automated with a combination of advanced technologies, saving time and money.

Is automation good for manufacturing?

Absolutely. Automation is already widely used in the manufacturing industry through physical robots and software applications, yet, many clerical tasks are still performed manually. Now, a new alternative exists. Talk to experts.

How can a manufacturing company determine where it needs automation?

Nividous can help you with this piece as part of the engagement process. But if you decide to get started on your own, follow these steps.

First, identify an area where there is a high volume of repetitive manual tasks, such as document processing or data sorting.

Second, pick only processes that are simple and rule-based. Step-by-step processes are the best candidates for automation, while complex, subjective tasks usually need dedicated human operatives.

Lastly, contrast the selected processes on a grid that shows business value vs. complexity to determine the best process to start with.

How can I get started with automation?

First, identify rule-based, time-consuming, repetitive tasks that can be easily handled by RPA bots. As mentioned above, Nividous can help you with this, if desired.

For these tasks, deploy automation and observe closely. As you watch your processes unfold over the trial period, gather data around the following:

- Are we saving time?

- Does that saved time translate to reduced costs?

- Are my employees able to switch their focus to more complex tasks during their workdays?

- Does the automated process seem more likely to produce error-free data/results?

- Are bots and AI technologies more effective at completing these tasks than employees?

Once you have time to observe the success of automation with tactical tasks, scale up. You can identify more processes, deploy more bots, and connect each stage of the process with other types of automation listed in this article.

Who does manufacturing automation benefit—executives, shareholders, employees, or others?

Automation can benefit everyone within a manufacturing organization. It is often most appreciated by the employees whose time is saved by automating time-consuming tasks.

But in the end, the time and cost savings created by automation benefits shareholders and executives as well. Plus, improved processes also have the potential to increase customer satisfaction.

Why is automation so important for manufacturing?

Using automation lowers costs—the cost of operations, human costs, and time costs. The ROI is palpable for the vast majority of manufacturing companies.

How long does it take to get up and running with automation?

With the Nividous Quick Start Guarantee, it’s possible to implement a trained Nividous Bot in as little as three to four weeks. If you’re satisfied with the results, you can scale up immediately. Contact us to learn more.

This blog is initially published on July 21, 2018.