If you’re interested in refining the way your company runs, boosting efficiency, and uncovering ways to widen your margins and save money, chances are you’re considering at least a rudimentary form of automation — if not a fully intelligent automation solution.

Before you can implement the automation solution of your choice, however, you must first understand your business processes.

There’s no good way to skip to the end product without first investigating your company’s individual processes and determining how automation (or even some simple optimization efforts) could make a significant difference to efficiency, employee and user experiences, or your bottom line.

This middle, investigational step is known as process mining. Here’s how it works and what you need to know.

Want the benefits of process mining without the hassle? Let Nividous uncover the fine details of how your employees spend their time. Contact us to get started.

How Process Mining Can Help Your Business Save Time (And Therefore Money)

What is process mining?

Process mining is a method of discovering what your business processes and workflows consist of in great detail.

You could, for instance, use process mining to find out what tasks employees must complete as part of working through a given process, how they’re using tools to accomplish those tasks, how long the process takes, and which common setbacks often contribute to frustration and wasted time.

How is process mining done?

Typically when people talk about process mining, they’re referring to the use of a specific technology that drills down into the details of business processes and uncovers what’s really going on under the surface.

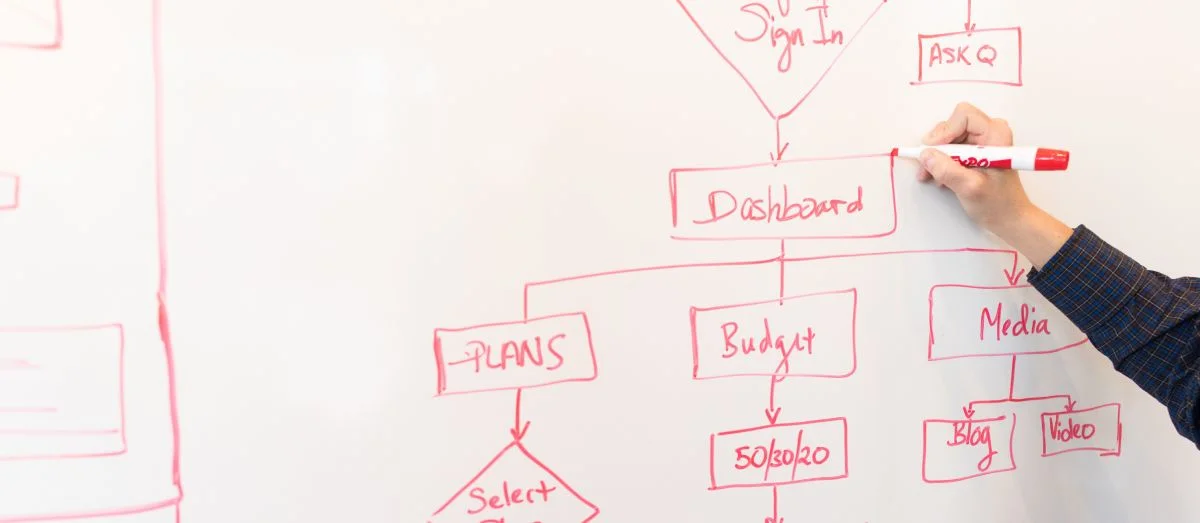

These technologies usually look at the tools employees have installed on their computers as well as the accompanying log files to determine how much time each employee spends using each program and what tasks they are performing. The process mining tool will monitor how frequently the employees switch back and forth between programs or how much data gets sent to other programs. This information is pieced together to construct the business processes in a draft form which can be manually validated and then formally documented, optimized and automated where possible.

Interestingly, process mining can also be done manually. A human process miner would meet with people at the company, have in-depth conversations about their daily tasks, and document all the steps they take and the tools they use to do their jobs.

Sifting through business processes manually might seem like a waste of time when tools exist that promise to do the same thing much faster and with greater detail. However, the hype of automated process mining tools often fails to live up to the reality.

Most of the time, the results generated by these tools require significant refinement and manual readjustment, to the point where manual process mining might have actually saved time.

The trouble is, human beings rarely sit down to work on a task and complete that task from beginning to end without interruption. When a person pops over to check their email, walks away to grab a cup of coffee and becomes absorbed in conversation with a coworker, or decides to switch tracks mid-task and focus on something else, the automatic process miner will log these movements and the extra time taken, and it can throw off the final result.

As an intelligent automation company, we believe analyzing processes is essential to introducing automation into any workflow. And while we do offer an automated process mining tool as part of the Nividous Intelligent Automation platform, we encourage clients to use this tool to augment and assist a manual process mining operation rather than try to completely replace the manual components. While technology can certainly help, simply talking to employees and reconstructing their perceptions of how they complete tasks is often the key to uncovering the inner workings of your business processes.

While technology can certainly help, simply talking to employees and reconstructing their perceptions of how they complete tasks is often the key to uncovering the inner workings of your business processes.

Do process mining techniques vary across industries or departments?

A shipping company operates entirely differently from a manufacturing company, which in turn is very different from a retail company. Therefore, the processes each company has will vary widely. Even within your own company, you may be interested in mining the processes for your HR department, finance, and IT.

The good news is you don’t need to feel intimidated by the idea of coming up with different process mining techniques for each department, or for different companies under your purview. The techniques for mining each process should largely be the same whether you’re investigating your invoice payment workflows or diving into how your employees make shipping arrangements.

Regardless of industry or department, process mining consists of the following steps:

- Tracking the way employees do their work

- Identifying workflows from beginning to end

- Identifying sticking points, inefficiencies, or bottlenecks that need a solution

- Documenting these details

- Devising a plan for automation, optimization, or other next steps

What can process mining do for your business?

Simply discovering the hidden details of your business processes does little good unless you ultimately plan to optimize or automate them. That’s why process mining is typically done during the exploratory phases before implementing a workflow automation plan.

While automation is the end goal that can boost your revenue, cut costs, eliminate the potential for human errors, and reduce the time and resources required to complete processes, it’s difficult to put together an effective automation strategy without thoroughly understanding your processes and how they might be improved. Process mining isn’t simply an additional, optional way of understanding more about how your company functions; it’s a crucial step in the broader journey toward automation and greater efficiency.

As such, process mining by itself isn’t likely to save your business any time or cut down on costs. It opens the door for automation to revolutionize the way your company gets work done. In turn, automating your processes is what provides the real benefits. Saved time equals saved money; fewer errors means less time wasted correcting them; and happier employees result in less turnover. These are just a handful of ways your company can see benefits from automation; but you can’t get there without first doing the work of process mining.

Process mining by itself isn’t likely to save your business any time or cut down on costs. It opens the door for automation to revolutionize the way your company gets work done.

Even if you’re not ready to fully automate your workflows, process mining can still help your company identify areas that need to be improved.

For example, if you discover that far too much time is wasted when your employees have to navigate a confusing application, you might consider using desktop or attended automation to handle some of the trickier steps, adding helpful tips to guide employees efficiently through the menus, or opting for a different application altogether. You may be able to reduce sticking points, efficiently balance workloads, and cut out extraneous steps in the process without any automation at all.

How can you get started with process mining and automation?

Keep in mind that you don’t need to have a fully-formed plan in mind before you reach out. Many of our clients come to us with specific pain points, but others uncover issues they weren’t aware of before they began process mining. We’re just as happy to help you plan your roadmap toward automation as we are to build your custom automation solution once you pin down your ultimate goals.

In fact, there’s a clear benefit to contacting us before you’ve set your mind on a particular course of action. After we mine your processes, you may decide your original pain points are indeed high-impact issues, but you first want to address ten more urgent problems you didn’t know were occurring on a regular basis.

Once we identify these things, we will put them all on a chart that weighs the value to your business of automating each process against the complexity and the resources needed to automate them. These visualizations often help clients save hours that would have otherwise been spent deliberating about the best way forward.

Let Nividous experts handle your process mining and automation plans.

There’s no need to reinvent the wheel — and spend hours investigating your processes by hand — when Nividous experts are standing by to do it for you.